5 Operational Strategies

A best management practice (BMP) operational strategy is a plan to accomplish the monitoring and maintenance necessary over the lifespan of the BMP after its construction. For the purposes of this document, monitoring means the practice of collecting BMP qualitative and quantitative data over time to provide information regarding its performance and condition. Maintenance means the care of a BMP using procedures to promote intended functionality and longevity of performance. This chapter presents information regarding routine and non-routine operational strategies, factors that should be considered when an operational strategy is being developed for BMPs on a site, cost considerations, prioritization and performance feedback.

The information provided in this chapter may also be used to develop an operations, monitoring and maintenance template for ongoing BMP operations. Resources presented in this section include case studies, sample forms/checklists/reports, and example monitoring/data collection plans to assist users in operations and maintenance (O&M) performance documentation (Figure 5-1).

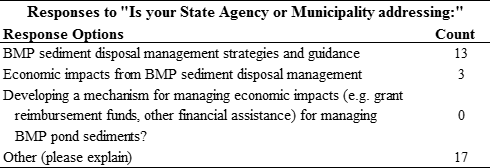

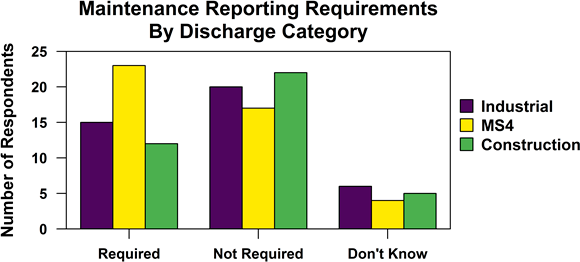

Figure 5-1. ITRC survey results for Question #6. (Appendix A)

5.1 Routine Operational Strategies

A Routine operational strategy considers the monitoring and maintenance activities that are generally based on a set schedule and involve tasks that are carried out on a regular basis. Examples of routine maintenance include removal of trash and debris from inlets and ponding areas, mowing, weeding or pruning plants, minor sediment removal, leveling of filtration media and replacement of filter cartridges in manufactured BMPs. These activities keep the BMP functioning as designed and work to prevent a future failure. The BMPs do not need to be taken off-line to perform routine maintenance. This type of maintenance is carried out independent of inspections and reports and is specifically tailored for the individual type and location of the BMP. Sites located in highly urbanized areas that receive high amounts of litter and other debris will need more frequent routine maintenance than the same BMP located in a less developed area.

Although routine maintenance is performed independent of inspections, it is important to keep records of maintenance activities. Approximately half of the agencies surveyed require maintenance documentation for municipal separate stormwater sewer system (MS4) and industrial stormwater BMPs (Figure 5-2). Records of specific routine maintenance activities performed over a range of BMPs provide feedback to refine the maintenance schedule and ensure that BMPs in problem areas receive necessary attention. Records help assess the level of effort in maintaining BMPs to ensure efficient use of time and resources. Records showing recurring maintenance activities may indicate an ongoing problem or failure of a BMP component that requires a higher level of effort than is provided by routine maintenance. For example, a bioretention basin with records showing the need for additional material to level the media could indicate a slow collapse of the underdrain system. With this information, a more extensive investigation of the BMP and changes can be made to correct the deficiency before a total failure occurs.

Effective stormwater management programs have an educational and outreach component, which can reduce the need for routine maintenance action and ensure that serious failures are avoided. Program outreach communication improves BMP operation and maintenance along with the other program elements. When people are educated to understand the objective of stormwater management, (i.e., to protect and preserve public and natural resources), they are much more likely to develop an understanding of BMPs and how they function (USEPA 2005). Tools that provide this educational element include signage noting BMP locations and illustrating their role in stormwater management, as well as storm drain medallions denoting the urban infrastructure’s direct connection to the natural system. The sense of stewardship that grows out of this understanding of the larger objectives and systems results in people taking ownership of the operation of BMPs and makes them more likely to avoid throwing trash into facilities and more likely to report observed problems.

Figure 5-2. Survey responses to survey question, “Does your Agency have mandatory maintenance reporting requirements for post construction BMP performance? (Appendix A)

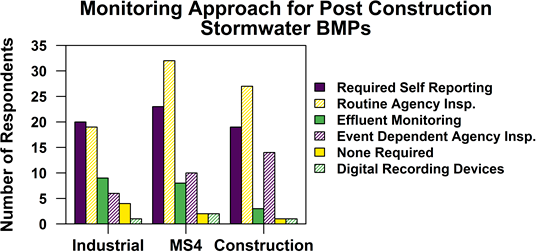

Post-construction monitoring requirements vary widely across jurisdictions. Survey respondents indicated that monitoring primarily occurs through routine agency inspections, and permits require self-reporting (Figure 5-1). These are all examples of routine monitoring.

5.2 Non-routine Operational Strategies

Non-routine maintenance results from an observation made in an inspection or maintenance report or from a complaint about a failure. Non-routine maintenance involves corrective measures that are provided and occur on an as-needed basis. These include repair to inlet or outlet structures; repair to eroded slopes, embankments, or flow paths; replacement of filter media that is no longer effective; removal of accumulated sediment; and replacement of dead plantings. Non-routine maintenance usually requires specialized training for maintenance staff. Special equipment for excavation, compaction and drainage infrastructure installation may be required for more extensive repairs. The most protective maintenance programs utilize routine proactive measures to address operational needs and non-routine reactive measures to address unforeseen issues.

5.3 Predictive Maintenance

Routine and non-routine maintenance are critical components to the ongoing operation of stormwater BMPs. However, thanks to the ever-growing technology industry, a third category of maintenance is now available, predictive maintenance. Predictive maintenance is the ability to forecast and perform necessary repairs, prior to failure, with little to no disruption to system operations; potentially saving valuable resources. A stormwater system operator can only achieve predictive maintenance through the incorporation of technology along with a clear operations plan.

The technology required to achieve predictive maintenance falls within the scope of the Internet of Things (IoT). The IoT is the network of physical objects or things embedded with electronics, software, sensors and network connectivity that enables these objects to collect and exchange data (International Institute for Analytics). Stormwater BMPs are fitted with sensors and software that are connected to the cloud. This provides visibility into a BMPs performance and supports operators in their decision-making processes. Incorporating IoT into stormwater BMPs can improve water quality, reduce flooding and provide valuable insights into BMP performance. An example of IoT in action includes forecast-based decision making in retention ponds to reduce wet weather discharge, increase infiltration, increase retention time, and maximize capacity of the BMP. Through installation of a level sensor and actuated valve in the outlet control structure of a retention pond, real time information may be transmitted to a cloud-based platform and water levels may be controlled remotely via a user’s interface from anywhere they have a network connection. Taking action prior to wet weather events may alleviate flooding concerns and maximize the efficiency of the BMP. When multiple BMPs are connected within a watershed, flood management becomes feasible and downstream water quality can be improved. Current applications of this technology may be viewed at www.optirtc.com. (Lefkowitz 2015)

Incorporating IoT into stormwater BMPs requires thoughtful planning and consideration. The information gathered through the incorporation of the technology is only useful when analytical methods are applied to support decision-making processes. With proper analytical review, a feedback loop is created in which operators make informed decisions on when and how to manage, repair and replace stormwater BMPs. This can lead to greater O&M efficiencies, putting less stress on limited resources and time by having real time knowledge of the status of the system when properly incorporated.

5.4 Technology vs. Performance-based Strategies

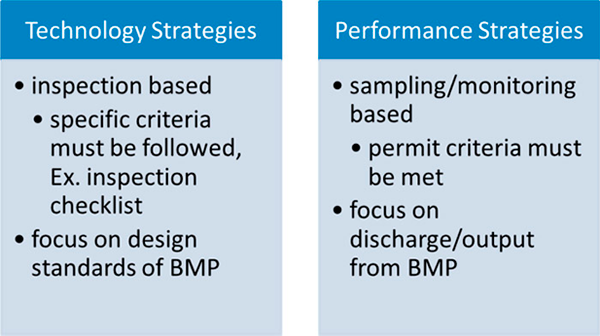

Stormwater BMPs are designed and constructed to meet specific stormwater management goals related to water quality or quantity. These goals are met by applying either performance-based criteria or technology-based criteria. A performance-based strategy demonstrates compliance with a stormwater management goal by focusing on the discharge or output from a BMP and verifies that the discharge meets or exceeds that goal. In contrast, a technology-based strategy focuses on the physical characteristics of the BMP, in its specific operating environment, and demonstrates compliance by conforming to design standards set by the stormwater management program. Prior research, testing and experience with the BMP standard design provides assurance that the management goal will be met and analysis of the discharge from the BMP is not necessary. The concepts of technology- and performance-based criteria can be applied to O&M situations as well.

Figure 5-3. Technology Vs. Performance based Strategies

Many non-routine maintenance actions occur because of some failure in the operation of the BMP and are therefore considered performance-based strategies. For example, a citizen reports water pooling for extended periods of time in a bioretention filter. This report results in an investigation and maintenance, or repair, to the facility based on the observed failure in the BMP performance or function. All of the other aspects of the bioretention filter may look fine, but some problem is causing a failure in performance that leads to the necessary maintenance activity.

Routine inspections and maintenance activities are technology-based approaches. These activities are in response to a schedule, not any observable performance factor. For example, routine maintenance performed on a bioretention basin can include mowing, pruning, leveling of the media and removal of trash and sediment from the inlet and outlet structures. Although there may be no observed failure in performance of the filter, the technology-based maintenance actions are required because the design standards for the basin specify that the grass shall not be longer than six inches in height, the plants shall not stand higher than four feet, the media shall be level and inlets and outlets shall be kept clear of obstruction by debris and sediment. The proscriptive nature of technology-based criteria tends to work well with maintenance staff who may not be familiar with the performance goals of the BMP, but understand the specifications of the standard and can provide the maintenance actions needed to keep the BMP in conformance with those specifications.

5.5 Considerations in an Operational Strategy

The first consideration in developing an operational strategy is identification of an inventory of the BMPs within the jurisdiction of the maintenance program. The inventory should include information locating each BMP and describing its specific type and function. Additional information detailing the facility’s context, construction and connections to the overall drainage system will aid in developing the maintenance strategy.

Once the BMPs are inventoried and assessed, a plan for carrying out inspections and maintenance activities can be developed, aiming to ultimately achieve the performance goals. The plan should be devised to fit both the level of need for maintenance presented by the inventoried BMPs and the ability of the organization to meet those needs. There are very few organizations that have all of the resources required to carry out all of the actions needed to maintain BMPs. Therefore it is necessary to plan what activities will be performed in-house and what activities will be provided by parties outside of the responsible organization. Once the scope of operations to be conducted in-house is determined, detailed schedules, policies and procedures for inspections and proactive maintenance activities can be developed. In conjunction with the development of schedules and procedures, standard documents should be created to ensure consistency in the execution of maintenance activities. These documents include standard inspection report checklists and forms, notices for needed reactive maintenance, documentation of maintenance actions provided, and other more narrowly focused documents, depending on the level of sophistication intended for the program. These informational and directional documents may be compiled into a maintenance handbook where all the program materials are readily available.

Record keeping and tracking is necessary to maintain the BMP inventory and the associated standard procedures and documents. The tracking system should document conditions reported in inspections, actions taken, actions required in the future and provide a means of analyzing collected data to identify trends and/or deficiencies in the maintenance program. From this tracked data, informed decisions can be made regarding maintenance planning, staffing and other program resource needs, budgeting and unforeseen factors that are revealed in data trends. The level of complexity or sophistication of the tracking system will be developed to match the level of the maintenance program itself.

Once the scope of BMPs to be covered by the maintenance program is known, the facilities should be evaluated to assess how technologically complex they are and what level of maintenance they will require. BMPs functioning on precise chemical treatment processes or management of stormwater through a train of connected BMPs, will require a higher level of expertise, skill and ability from the maintenance staff than less complex BMPs. This may require a strategy to include contracting maintenance work on complex BMPs, outside of the responsible organization, to parties that have the required level of expertise. Likewise, contracting maintenance work may be a necessary consideration if activities are required that employ specialized equipment such as excavating or grading machinery, often needed to carry out reactive maintenance operations.

5.5.1 Geographic Factors

It is important when developing an operational strategy to be aware of geographic factors such as eco-regional variation, climate, ecology, soils and geology, groundwater elevation, as well as population density variation. These factors can influence operations in a variety of ways, such as the frequency of monitoring required and expected maintenance. The following sections discuss varying geographic factors; however, it should be noted that this not an exhaustive list and additional factors may need to be considered for unique environmental conditions.

5.5.1.1 Eco-regional Variation

5.5.1.2 Ecology and Wildlife

5.5.1.3 Geography

5.5.1.4 Soils and Geology

5.5.1.5 Groundwater Elevation

5.5.1.6 Population Density Variation – Visibility, Site Contamination, Land Use

5.5.2 Cost Factors

Cost of operations should be incorporated into any evaluation of BMP options for a site. Such costs can be difficult to predict in advance; however, planning for these costs must be initiated early to ensure that funds are available to perform the necessary work. For most BMPs, routine annual maintenance costs are approximately 2-4% of the original construction cost, and non-routine costs require an additional annual allocation of approximately 2-5% of the original construction cost (King 2011) Northern Virginia Planning Commission (Commission 2000). The USEPA also provides a cost estimator for updated average annual national and regional operational costs. This annual allocation should be saved in a long-term maintenance fund to be used when these activities are required. The American Society of Civil Engineers developed a book titled, Cost of Maintaining Green Infrastructure for purchase at the following website ASCE (American Society of Civil Engineers).

Several tools are available to assist owners in budgeting for the lifecycle of BMPs, including maintenance. For example, the BMP Evaluation Tool presented by the National Cooperative Highway Research Program (Taylor 2014), provides an estimate of average or likely capital, routine and non-routine maintenance, and retrofit (USEPA 2017b) and whole-lifecycle costs. The Whole Life Cost spreadsheets integrated into the tool calculate individual BMP maintenance costs based on national averages. The estimates can be adjusted by adding or editing the maintenance activities already built into the spreadsheets. The BMP whole-lifecycle cost estimate and summary in the spreadsheets enable users to plan and budget for future O&M requirements.

5.5.2.1 Site-specific Cost Factors

5.5.2.2 Frequency Cost Factors

5.5.2.3 BMP-specific Cost Factors

5.5.2.4 Personnel Cost Factors

5.5.2.5 Waste Characterization and Disposal Cost Factors

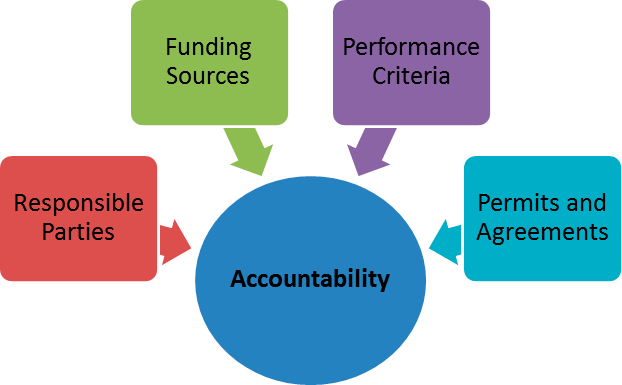

5.5.3 Accountability

Accountability is an increasing point of focus for stormwater BMP management (Figure 5-5). Operation, Maintenance and Monitoring (OM&M) plans are only effective if stormwater BMP operators are held accountable for BMP performance. To illustrate this point, USEPA has included accountability as the key component of its model stormwater O&M ordinance. The model ordinance specifically calls out the necessity to identify and record the O&M responsible party, funding sources, repairs and inspections (USEPA 2015b). OM&M accountability provides reasonable assurance that BMPs will properly function, yielding water quality benefits, while meeting legal requirements, protecting public safety and the communities’ financial investments. Identification of the responsible parties in legally binding agreements provide strong incentives for responsible parties to ensure proper maintenance activities are performed or risk non-compliance penalties (USEPA 2015a).

Identification of the OM&M plan responsible party has improved over the years with the addition of technology and tools, such as, geographic information systems (GIS) and asset tracking software. Inspections have also gained traction with many local municipalities employing inspectors with technology and tools to identify gaps in BMP performance. Local enforcement, however, appears to be hit or miss due to one key element that is generally lacking in execution of stormwater ordinances – funding sources. Implementation of stormwater fees, performance bonds, and property owner associations are working to fill this budget gap, but many private parties struggle to clarify and account for funding prior to BMP failure.

Permits and maintenance agreements, discussed in greater detail in the following sections, are two key legal documents utilized to compel accountability for stormwater BMP performance. Additionally, performance bonds, easement and access agreements, and a variety of other real estate agreements may be drafted and executed or recorded for identification of responsible parties and accountability of performance. At this point, it is critical to identify a step that is often overlooked during real estate transactions – the transfer of these agreements as the property changes hands and the necessity of identifying the new responsible party. BMP ownership may change multiple times through the lifespan of the asset. For each of these transition periods, it is important to have the responsible party identified and the OM&M plan active to achieve optimal BMP performance.

Figure 5-6. Accountability.

5.5.3.1 Defining Responsible Parties

5.5.3.2 Permits

5.5.3.3 Maintenance Agreements

5.5.4 Prioritization & Frequency

Prioritization and frequency are important factors when developing an operational strategy for a stormwater BMP. Depending on the type of BMP, or train of BMPs, the operational strategy should be evaluated for the entire lifecycle of the BMP.

Prioritization refers to the relative intensity of operational items with respect to the beginning, middle or end of the BMP lifecycle. These may be referred to as frontloaded, averaged or back-loaded priorities. Frequency refers to the expected number of operational events during a given period.

In order to control costs, higher effort operational tasks may be staged throughout the lifecycle of the BMP. As discussed in preceding portions of this document, informed design (e.g., upsizing, capacity selection, treatment train development), installation (e.g., effective QA/QC of installation), and operations (e.g., proactive versus reactive maintenance) may alleviate higher effort maintenance activities and cost. The frontload versus backload of operational tasks is very important for BMP selection. For example, a wet pond can be designed to provide sufficient solids accumulation such that a dredging activity is not required until very late in the life of the BMP.

Likewise, frequency can be used to adjust the operational requirements such that high effort maintenance activities can be reduced to smaller effort, but more frequent operations. Proactive maintenance is often characterized by frequent, smaller effort events versus singular, higher effort events. For example, a structural BMP that is expected to experience a high sediment load due to site development activities will likely have a frontloaded, high frequency operational strategy, whereas oversizing the actual capacity of the BMP may result in large scale, less frequent operations activities. Of course a cost-benefit analysis can be undertaken to distill a good, better, best set of options for capacity versus anticipated monitoring and maintenance.

5.5.4.1 Expected Lifecycle

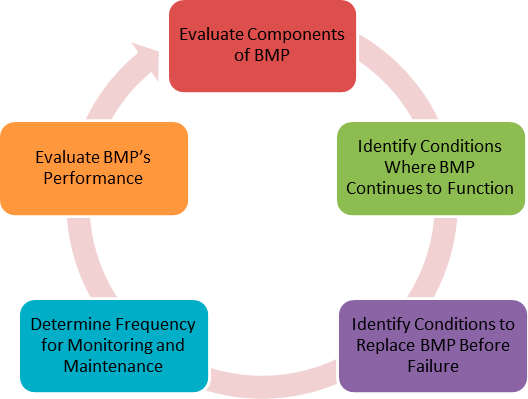

Examination of the expected lifecycle of a BMP is another important aspect of developing prioritization and frequency expectations for an operational strategy (Figure 5-5). Depending on the type of BMP (structural versus non-structural), there may be structural (e.g., subsurface concrete structures), mechanical (e.g., weirs), chemical (e.g., adsorption canisters), or physical (e.g., trash nets) components as part of the BMP or train of BMPs. Lifecycle management should be considered when employing any BMP. A useful life of the various BMP components needs to be evaluated in order to assist in the development of inspection and maintenance frequencies. Certain elements within the BMP require more frequent inspections and/or maintenance due to capacity limitations (e.g., adsorption canisters, trash nets). These tend to be obvious and are identified either by the manufacturer of the BMP or the operators. Examination of the structural and mechanical features of the BMP are just as critical, but due to the nature of the BMPs, tend to be back loaded with respect to inspection and maintenance and are often not considered until the BMP has already reached its end of life. For example, a failure of a sub-surface concrete vault is typically characterized by cracking, erosion or spalling well before a structural incident occurs. Operational management of the BMP lifecycle requires recognition of what conditions the BMP will exist under. Developing an effective inspection and maintenance program allows detection of life ending issues before they occur.

Figure 5-7. Lifecycle of a BMP.

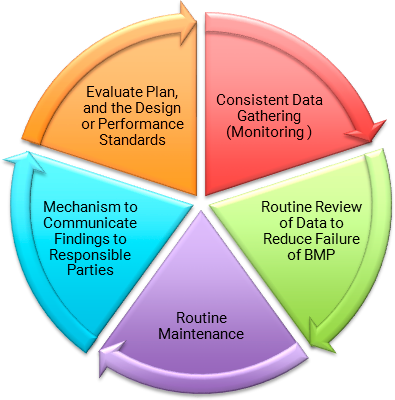

5.5.5 Performance Feedback Loop

Stormwater BMP performance is largely dependent upon the creation and implementation of an OM&M plan. Over time, without the implementation of an OM&M plan, a stormwater BMP will eventually fail causing negative impacts to water quality. However, even when an OM&M plan is properly implemented, a stormwater BMP will fail if no performance feedback loop (Figure 5-6) exists. The performance feedback loop provides a mechanism to identify and remedy gaps present in individual BMP performance Asset Management Programs for Stormwater and Wastewater Systems: Overcoming Barriers to Development and Implementation. As previously stated, preventative and reactive maintenance is necessary for stormwater BMPs to operate effectively. These maintenance intervals are generally influenced via the feedback received through various inspections and checklists; without this information an operator cannot determine whether a BMP is operating effectively or not. Yet it is important to take a step back and look at the performance feedback loop in a broader context.

Figure 5-8. BMP performance feedback loop.

Designers, installers and operators can all benefit from insights gained through an effective performance feedback loop. Use of a tracking system to capture BMP data consistently over a period of time provides valuable information to improve the design, implementation and operation of BMPs. This data gathering exercise provides a feedback loop to critical insights of which factors most influence BMP effectiveness and failure. Limiting instances of failure leads to improved water quality. In addition, systematic review can steer program strategies and provide a basis for budgeting future repairs and projects. Use of a performance feedback loop, beyond the individual BMPs, assists in identifying and implementing ongoing program improvements to better protect water quality. (Taylor 2014)

Critical elements to the performance feedback loop include:

- Consistency in data gathering

- Routine review, evaluation and collating the information on a routine basis identifies trends early and reduces failures

- Effective communication – there must be a mechanism to provide findings back to the relevant parties

- Metrics – establish design or performance standards that are measurable, some targets will be set and others may change depending upon requirements and expectations

- Technology – from systems to sensors